AI in manufacturing is becoming more common than you might think.

Increasingly, technology plays a major role in how products get made on the factory floor. Manufacturing plants can resemble high-tech laboratories with robotic arms handling repetitive tasks and algorithms, ensuring that products are made according to manufacturer specifications.

Industrial titans like General Electric (GE 0.68%) and Siemens have embraced artificial intelligence as the technology offers a number of advantages, including minimizing defects and errors, reducing downtime, and saving on costs.

In this look at AI in the manufacturing industry, we'll discuss what artificial intelligence is, how it plays a role in manufacturing, and review several examples of how AI is used in manufacturing.

Machine Learning

What is artificial intelligence?

What is artificial intelligence?

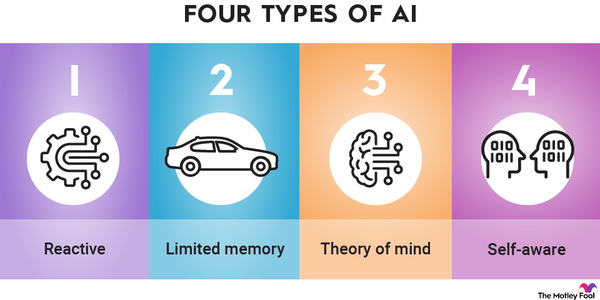

Artificial intelligence is a technology that allows computers and machines to do tasks that normally require human intelligence.

This includes a wide range of functions, such as machine learning, which is a form of AI that is trained data to recognize images and patterns and draw conclusions based on the information presented.

There's also computer vision, which is widely used in manufacturing; natural language processing, which includes tools like ChatGPT and other chatbots; neural networks; and robotics, which may be the most commonly used AI application in manufacturing.

Altogether, artificial intelligence capabilities allow manufacturers to redeploy human labor to jobs that machines can't yet do and to make production more efficient and cost-effective.

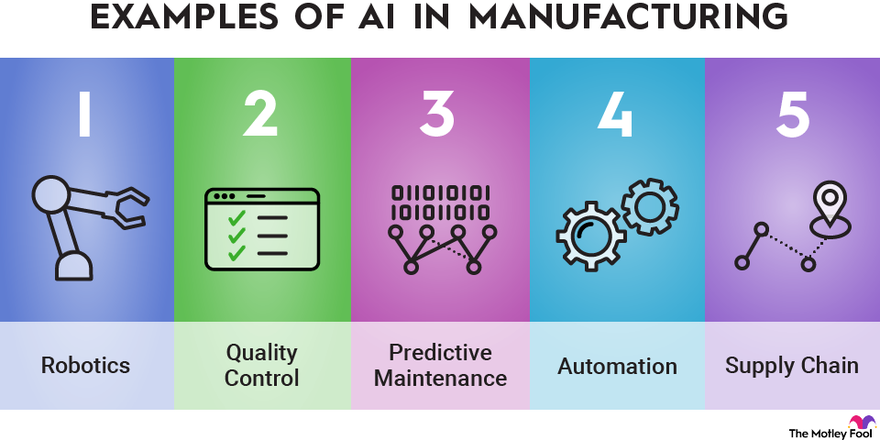

5 applications of AI in manufacturing

5 applications of AI in manufacturing

Manufacturing is one of many industries that artificial intelligence is changing. Keep reading to see five ways that artificial intelligence is being used in manufacturing today.

1. Robotics

When you imagine technology in manufacturing, you probably think of robotics. Now, more than ever, robots play a major role in manufacturing.

Companies like Amazon (AMZN 3.43%) use robots to move items back and forth and to pick and pack orders. Ford (F -1.92%) uses robots to operate 3D printers, and the robots save time by running them unsupervised overnight, using 3D designs that have been uploaded to the printer. While a human needs to give them the design, the process itself is autonomous.

Cobots or collaborative robots are also commonly used in warehouses and manufacturing plants to lift heavy car parts or handle assembly. Often, cobots are capable of learning tasks, avoiding physical obstacles, and working side-by-side with humans.

Expect robotics and technologies like computer vision and speech recognition to become more common in factories and in the manufacturing industry as they advance.

2. AI in quality control

Quality control is a key component of the manufacturing process, and it's essential for manufacturing. Making machines like automobiles can be deadly if there are errors.

Here, AI is also being applied in a number of different ways. AI-powered vision systems can recognize defects, pull products or fix issues before the product is shipped to customers.

Semiconductor companies, including Samsung (SSNL.F -28.74%), Google (GOOGL 10.22%) (GOOG 9.96%), and NVIDIA (NVDA 6.18%) also use machine learning for quality control, optimizing chip design, and improving manufacturing.

Semiconductor

Quality control is one area where AI systems consistently outperform manual testing processes done by humans. AI machines are also able to optimize production and figure out the root cause of a problem when there is an error.

3. AI in predictive maintenance

Maintenance is another key component of any manufacturing process, as production equipment needs to be maintained.

This is where predictive maintenance comes in. Predictive maintenance analyzes data from connected equipment and production equipment to determine when maintenance is needed. Using predictive maintenance technology helps businesses lower maintenance costs and avoid unexpected production downtime.

Companies like IBM (IBM -1.05%) provide predictive maintenance technology that Washington, D.C., uses to help maintain its water hydrants, for example. Similarly, C3.ai provides predictive maintenance systems for utility companies, such as an electric grid serving more than 7 million customers. Its system relies on machine learning to prevent asset failures before they happen.

4. Automation

Automation is often the product of multiple AI applications, and manufacturers use AI for automation in a number of different ways.

Robotic process automation (RPA) is the process by which AI-powered robots handle repetitive tasks such as assembly or packaging.

One 2022 survey found that 43% of manufacturing businesses already use RPA. The benefits they've found from automation include a reduction in operational costs by up to 40%; an increase in the manufacturer's control over processes; improved employee performance; and significantly lower downtime.

Some companies that use RPA in manufacturing include Whirlpool (WHR -0.39%), which uses robotic process automation to automate its assembly line and handle materials. So-called bots are also used for quality control checks.

Supply Chain

5. AI in the supply chain

Manufacturing goes beyond what takes place on the factory floor. It's crucial for every manufacturer to have a well-managed supply chain so they have the parts they need when they need them.

That's why manufacturers often use artificial intelligence systems for supply chain optimization, focusing on demand forecasting, optimizing inventory, and finding the most efficient shipping routes.

BMW (BMWYY 0.95%) for example, uses AI to predict demand and optimize inventory. In one example, the company installed an AI application to prevent the transportation of empty containers on conveyor belts. The tech also decides if a container needs to be attached to a pallet, and finds the shortest route for boxes to be disposed of.

AI systems can also take into account data from weather forecasts, as well as other disruptions to usual shipping patterns to find alternate route and make new plans that won't disrupt normal business operations.

Will artificial intelligence revolutionize the manufacturing industry?

Will artificial intelligence revolutionize the manufacturing industry?

It's clear that artificial intelligence is already having an impact on the manufacturing industry. That influence will continue to grow.

Unlike some other industries, generative AI technologies like ChatGPT seem less likely to have an impact on manufacturing. But other forms of AI tech, like robotics and machine learning applications, will push the envelope, helping manufacturers produce goods more efficiently, relieve human labor, and eliminate errors that lead to product recalls or even real-world accidents.

Some forecasts estimate that the opportunity in artificial intelligence will be worth trillions of dollars. If you're looking to invest in AI manufacturers, you can consider some of the stocks above or take a look at other AI stocks, machine learning stocks, or AI ETFs.